Behind each vinyl record lies an intricate process, various techniques that transform raw materials into musical treasures. In this article, I’ll peel back the curtain on the artful steps of recording, mastering, and pressing that breathe life into vinyl records. As I unravel how vinyl records are made and explore the craftsmanship that produces these iconic spinning discs, get ready to be captivated by the story of how music’s oldest medium continues to resonate with souls across time.

Raw materials used in the making of vinyl records

Vinyl records are made using a specific type of plastic called polyvinyl chloride (PVC). The raw materials used in the production of vinyl records include:

- PVC resin: It is a thermoplastic polymer that can be softened by heating and molded into the shape of a record.

- Stabilizers: they prevent the PVC from degrading during the manufacturing process and ensure the longevity of the finished product. Common stabilizers include metal salts such as lead, calcium, and zinc compounds.

- Plasticizers: they are added to the PVC to make it more flexible and easier to work with during the pressing and molding stages. Common plasticizers used in vinyl record production include diethylhexyl phthalate (DEHP) or other phthalate derivatives.

- Pigments and dyes: colorants are added to the PVC mixture to give the vinyl records their distinct colors. Various pigments and dyes are used to achieve different shades and patterns.

- Lubricants: they help to reduce friction and aid in the manufacturing process by preventing the PVC from sticking to molds and machines.

- Regrind material: during the manufacturing process, scrap or defective records are often recycled and mixed with fresh PVC to reduce waste and lower production costs.

It’s important to note that the process of making a vinyl record involves using a combination of these materials to achieve the desired audio quality and durability. However, the exact formulation may vary among different record-pressing plants and manufacturers. Additionally, there have been efforts to reduce the environmental impact of vinyl record production, including exploring alternative materials and eco-friendly practices.

Labels

The paper or cardboard stickers are applied to the center of the vinyl record on both sides. These labels serve several purposes and are an essential part of the overall record production process. I’m going to explain how labels are involved in the vinyl record manufacturing process:

- Label design: Before the vinyl records are pressed, labels need to be designed. Record labels typically include important information.

- Record pressing: During this process, the center labels are applied to the vinyl record. This is typically done by a machine that automatically places the labels in the center of the record on both sides.

- Aesthetic appeal: Many collectors appreciate well-designed labels, and they can become part of the appeal of owning physical vinyl records.

- Legal and copyright information: Labels often include this information, which is important for legal purposes and ensuring that the appropriate royalties and rights are attributed to the artists and copyright holders.

Other miscellaneous materials

In addition to the primary raw materials, the vinyl record manufacturing process may involve a few other miscellaneous materials and components, which include:

- Cardboard jackets or sleeves: They not only protect the vinyl record but also serve as a canvas for artwork, album information, and other visual elements.

- Inner sleeves: They are placed inside the cardboard jacket and provide an additional layer of protection for the vinyl. Some inner sleeves are made of paper, while others are made of anti-static materials to reduce the risk of dust and scratches on the record.

- Outer plastic sleeves: These plastic sleeves help keep the records in pristine condition and prevent wear and tear.

- Master lacquers: This is a metal disc coated with a special lacquer that captures the audio signal during the mastering process. It is used to create metal stampers, which are then used to press vinyl records.

- Metal stampers: They contain a negative impression of the audio content. These stampers are placed in the pressing machine to press the grooves into the vinyl.

- Shrink wrap: In some cases, vinyl records may be shrink-wrapped for additional protection during shipping.

The process of creating vinyl records

In order to make vinyl records, there’s a lot of effort put into the whole process. I will describe in detail several stages, from recording the audio to the final pressing and quality assurance, so you have a clear understanding of the step-by-step process.

Recording

The process of manufacturing vinyl records begins with the recording of audio content. Musicians, bands, or artists record their music in a studio or live setting. This can include microphones, mixing consoles, and digital audio workstations. The recording engineer captures the performances and ensures high-quality audio. Once the recording is complete, the raw audio files are mixed to balance the levels of different instruments and vocals and then mastered to optimize the overall sound for the vinyl format.

Mastering the audio

During this step, the audio engineer fine-tunes the sound, making adjustments to equalization, dynamics, and stereo imaging to ensure the optimal possible sound quality. They also create a master recording that will be used for further processing, such as cutting the lacquer.

Cutting the lacquer

In this stage, the mastered audio is cut onto a blank lacquer disc using a lathe. The lacquer is coated with a special protective layer and then placed on the lathe. A cutting stylus moves across the lacquer’s surface, creating the grooves that represent the audio waveform. The cutting stylus is guided by the audio signal from the master recording, and it physically engraves the grooves onto the lacquer in real-time. The quality of the cut is essential, as it directly affects the sound of the final vinyl record.

Creating the stamper

Once the lacquer is cut, it becomes the “master disc” from which metal stampers are created. The lacquer is covered with a conductive layer and is immersed in a chemical bath to create a metal negative known as the “father.” The father is then used to create the “mother” by electroplating it with nickel. Finally, the mother is used to create the “stamper” by electroplating it with nickel again. The stamper is a positive metal disc with the same audio information as the lacquer but in reverse form, and it will be used in the pressing process.

Pressing the record

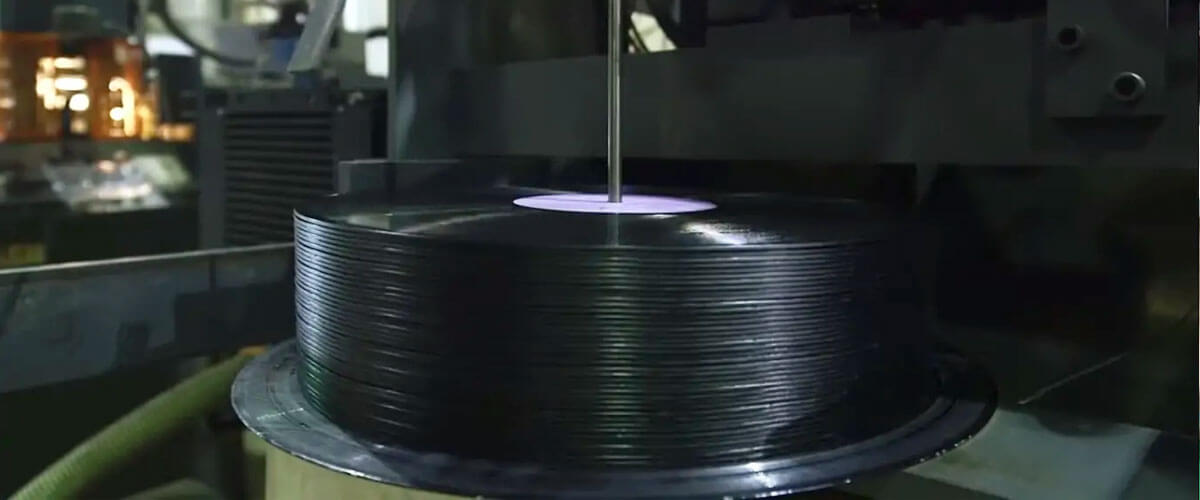

This is a time when vinyl records are physically produced. The stamper is placed in the center of a hydraulic press. Vinyl pellets are heated and softened. A puck of molten vinyl is placed between the two stampers, and the press closes with tremendous force. The hot vinyl is squeezed between the stampers, and the grooves are formed in the vinyl as the stampers apply pressure. Once the vinyl has cooled and solidified, the press opens, and the new vinyl record is removed, complete with grooves and audio content. Reading an article about why vinyl records are so expensive will also be useful.

Quality assurance and final inspection

After pressing, each record is visually inspected for any defects or imperfections, such as bubbles, warping, or scratches. Sound tests may also be conducted to check for audio quality issues. Records that pass the quality check are then packaged with cardboard jackets, inner sleeves, and any other components before being distributed to stores or directly to consumers.

Creating vinyl records requires precision and attention to detail at each stage to ensure the best possible audio quality and a visually appealing product. The process combines traditional craftsmanship with modern technology to produce records cherished by audiophiles, collectors, and music enthusiasts worldwide.

![Connect a Turntable to Your Wireless Bluetooth Speakers [Easy Guide]](https://www.vinylrecordday.org/wp-content/uploads/2021/12/tuntable-and-sonos-speaker-300x150.jpg)